We will try to get back to you as soon as possible.

Okey

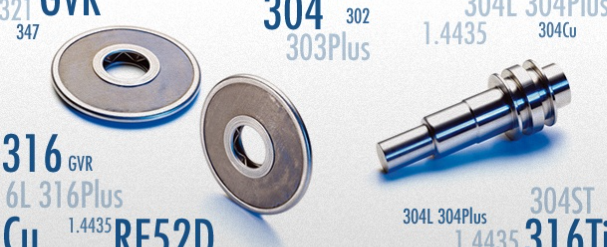

The reference steel for the chromium-nickel austenitic stainless steel category, it has good resistance to corrosion, cold deformability, and polishability. Its versatility makes it widely used for cutlery, grills, urban fixtures, and appliances, as well as in the automobile industry and in other applications.

| EUROPE | ITALY | GERMANY | FRANCE | UK | USA | ||

|---|---|---|---|---|---|---|---|

| EN 10088-3: 2005 |

(UNI 6900:71) |

(DIN 17440-85) |

(NF A 35-574-90) |

(BS 970 pt. 3 -91) |

AISI | ||

| Grade | N° | Werkstoff | N° | ||||

| X5CrNi18-10 | 1.4301 | X5CrNi1810 | X5CrNi18-10 | 1.4301 | Z7 CN 18 - 09 | 304S15 | 304 |

| C / max | Si / max | Mn / max | P / max | S / max | N/ max | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 0,07 | 1,00 | 2,00 | 0,045 | 0,030 | 0,10 | 17,50÷19,50 | 8,0÷10,5 |

| Size (mm) |

Hardness HB max* ** | Rp 0,2 (MPa) min | Rp 1 (MPa) min* | Rm (MPa)** | A5 (%) min** | KV (J) min | Resistance to intergranular corrosion | |

|---|---|---|---|---|---|---|---|---|

| in the delivery condition | in the welded condition | |||||||

| d≤100 | 215 | 190 | 225 | 500÷700 | 45 | 100 | YES | NO |

* Only for guidance

** The maximum HB values may be raised by 100HB or the tensile strenght value may be raised by 200 MPa and the minimum A% value may be lowered to 20% for bars of ≤35 mm

| Size (mm) | Rp 0,2 (MPa) min | Rm (MPa)0 | A5 (%) min* | KV (J) min |

|---|---|---|---|---|

| d≤10 | 400 | 600÷950 | 25 | - |

| 10<d≤16 | 400 | 600÷950 | 25 | - |

| 16<d≤40 | 190 | 600÷850 | 30 | 100 |

| 40<d≤63 | 190 | 580÷850 | 30 | 100 |

| 63<d≤100 | 190 | 500÷700 | 45 | 100 |

* Values valid only for size ≥5 mm

| Tensile strength levels | Rm (MPa) |

|---|---|

| +C 600 | 600÷800 |

| +C 700 | 700÷900 |

| +C 800 | 800÷1000 |

| +C 900 | 900÷1100 |

| +C 1000 | 1000÷1250 |

| +C 1100 | 1100÷1350 |

| +C 1200 | 1200÷1450 |

| +C 1400 | 1400÷1700 |

| +C 1600 | 1600÷1900 |

Note: the desired tensile strength level shall be evaluated depending on diameter required

| Size | A (%) max | Rm (MPa) max |

|---|---|---|

| 0,10≤d≤0,20 | 20 | 1050 |

| 0,20≤d≤0,50 | 30 | 1000 |

| 0,50≤d≤1,00 | 30 | 950 |

| 1,00≤d≤3,00 | 30 | 900 |

| 3,00≤d≤5,00 | 35 | 850 |

| 5,00≤d≤16,00 | 35 | 800 |

Note: If skin passed, Rm might be increased by up to 50 MPa

| Operation | °C |

|---|---|

| Hot forgings deformation | 900÷1200 |

| Solution annealing (water, air) | 1000÷1100 |