We will try to get back to you as soon as possible.

Okey

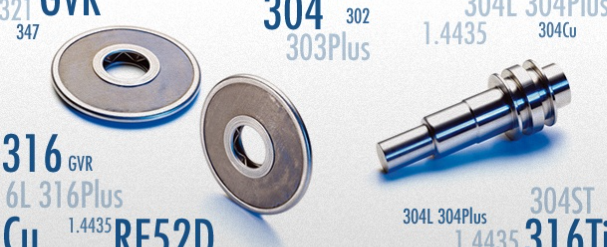

The addition of copper to the base characteristics of 304 significantly increases cold deformability. It is therefore used for fasteners and in general for cold moulded parts when they are complex and have extreme deformations.

| EUROPE | ITALY | GERMANY | FRANCE | UK | USA | ||

|---|---|---|---|---|---|---|---|

| EN 10088-3: 2005 EN 10263-5: 2001 |

(UNI 6900:71) |

(DIN 1654-5: 89) |

(NF A 35-574-90) |

(BS 3111 pt.2 -79) | AISI | ||

| Grade | N° | Werkstoff | N° | ||||

| X3CrNiCu18-9-4 | 1.4567 | - | X3CrNiCu18-9 | 1.4567 | Z3 CNU 18 - 10 | 394S17 | 302HQ |

| C / max | Si / max | Mn / max | P / max | S / max | N/ max | Cr | Cu | Ni |

|---|---|---|---|---|---|---|---|---|

| 0,04 | 1,00 | 2,00 | 0,045 | 0,030 | 0,10 | 17,0÷19,0 | 3,0÷4,0 | 8,5÷10,5 |

| Tensile strength levels | Rm (MPa) |

|---|---|

| +C 600 | 600÷800 |

| +C 700 | 700÷900 |

| +C 800 | 800÷1000 |

| +C 900 | 900÷1100 |

| +C 1000 | 1000÷1250 |

| +C 1100 | 1100÷1350 |

Note: the desired tensile strength level shall be evaluated depending on diameter required

| Size | A (%) max | Rm (MPa) max |

|---|---|---|

| 0,10≤d≤0,20 | 20 | 1050 |

| 0,20≤d≤0,50 | 30 | 1000 |

| 0,50≤d≤1,00 | 30 | 950 |

| 1,00≤d≤3,00 | 30 | 900 |

| 3,00≤d≤5,00 | 35 | 850 |

| 5,00≤d≤16,00 | 35 | 800 |

Note: If skin passed, Rm might be increased by up to 50 MPa

| Size (mm) |

As Treated (+AT) or Peeled (+AT+PE) | Cold Drawn (+AT +C) | Cold Drawn + Solution annealed (+AT +C +AT) | Cold Drawn + Solution annealed + Skin passed (+AT +C +AT +LC) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rm (MPa) max | Z (%) min | Rm (MPa) max | Z (%) min | Rm (MPa) max | Z (%) min | Rm (MPa) max | Z (%) min | ||||

| 2≤d≤5 | - | - | - | - | 600 | 68 | 650 | 63 | |||

| 5<d≤10 | 590 | 68 | 740 | - | 590 | 68 | 640 | 63 | |||

| 10<d≤25 | 590 | 68 | 700 | - | 590 | 68 | - | - | |||

| 25<d≤50 | 590 | 68 | - | - | - | - | - | - | |||

| Operation | °C |

|---|---|

| Hot forgings deformation | 900÷1200 |

| Solution annealing (water, air) | 1000÷1100 |