We will try to get back to you as soon as possible.

Okey

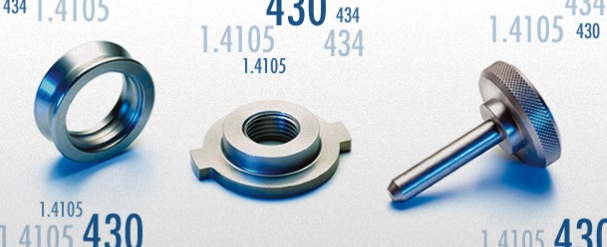

Steel similar to 430 with the addition of molybdenum, which confers a good resistance to atmospheric corrosion at room temperature and at higher temperatures.

| EUROPE | ITALY | GERMANY | FRANCE | UK | USA | ||

|---|---|---|---|---|---|---|---|

| EN 10088-3: 2005 |

(UNI 6900:71) |

(DIN 17440 - 85) |

(NF A 35-574-90) |

(BS 1554 -90) | AISI | ||

| Grade | N° | Werkstoff | N° | ||||

| X6CrMo17-1 | 1.4113 | X8CrMo17 | X6CrMo17-1 | 1.4113 | Z8CD17-01 | 434S20 | 434 |

| C / max | Si / max | Mn / max | P / max | S / max | Cr | Mo |

|---|---|---|---|---|---|---|

| 0,08 | 1,00 | 1,00 | 0,040 | 0,030 | 16,0÷18,0 | 0,90÷1,40 |

| Size (mm) | Hardness HB max* | Rp 0,2 (MPa) min | Rm (MPa) | A5 (%) min | Resistance to intergranular corrosion | |

|---|---|---|---|---|---|---|

| in the delivery condition | in the welded condition | |||||

| d≤100 | 200 | 280 | 440÷660 | 18 | YES | NO |

* Only for guidance

| Size (mm) | Rp 0,2 (MPa) min | Rm (MPa) max | A5 (%) min* |

|---|---|---|---|

| d≤10 | 340 | 540÷700 | 8 |

| 10<d≤16 | 320 | 500÷700 | 12 |

| 16<d≤40 | 280 | 440÷700 | 15 |

| 40<d≤63 | 280 | 440÷700 | 15 |

| 63<d≤100 | 280 | 440÷660 | 18 |

* Values valid only for size ≥5 mm

| Tensile strength levels | Rm (MPa) |

|---|---|

| +C 500 | 500÷700 |

| +C 650 | 650÷850 |

| +C 800 | 800÷1000 |

| +C 900 | 900÷1100 |

Note: the desired tensile strength level shall be evaluated depending on diameter required

| Size | A (%) max | Rm (MPa) max |

|---|---|---|

| 0,10≤d≤0,20 | 10 | 900 |

| 0,20≤d≤0,50 | 15 | 850 |

| 0,50≤d≤1,00 | 15 | 850 |

| 1,00≤d≤3,00 | 15 | 800 |

| 3,00≤d≤5,00 | 15 | 750 |

| 5,00≤d≤16,00 | 20 | 700 |

Note: If skin passed, Rm might be increased by up to 50 MPa

| Size (mm) |

As Treated (+AT) or Peeled (+AT+PE) |

Cold Drawn (+AT +C) | Cold Drawn + Solution annealed (+AT +C +AT) | Cold Drawn + Solution annealed + Skin passed (+AT +C +AT +LC) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rm (MPa) max | Z (%) min | Rm (MPa) max | Z (%) min | Rm (MPa) max | Z (%) min | Rm (MPa) max | Z (%) min | ||||

| 2≤d≤5 | - | - | - | - | 600 | 60 | 660 | 58 | |||

| 5<d≤10 | 600 | 60 | 710 | 57 | 600 | 60 | 640 | 58 | |||

| 10<d≤25 | 600 | 60 | 690 | 57 | 600 | 60 | - | - | |||

| Operation | °C |

|---|---|

| Hot forgings deformation | 800÷1100 |

| Annealing (air) | 750÷850 |